Former uncontrolled landfill

Phenoxy acids and methane in regional sand and gravel aquifer

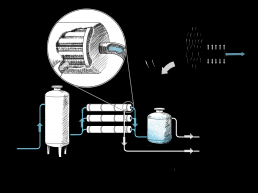

P&T plant with extensive testing facilities

Electricity production based on methane landfill gas with possibility for testing gas engines.

Several wells, in source and plume, with multiple screens which gives the possibility for extensive monitoring ie. MNA.

Meeting room, office space, toilet, Wi-Fi, 3x400v -160A.

CONTACT

Stengaardens Landfill, Hvalsø

Roskildevej 17B

4330 Hvalsø

Bente Højlund Hyldegaard

Region Sjælland

T: 29769307

E: behyl@regionsjaelland.dk

Site owner:

Region Sjælland

PRESENTATION OF THE SITE

REASON FOR THE SITE

The site is a former landfill contaminated with phenoxy acids. The site has been remediated since 1995 by P&T and since 2011 the gas has been extracted to prevent intrusion into nearby houses.

In 2013 Region Zealand purchased the ground on which the water treatment plant was build.

The plant vent through a complete reconstruction during 2015 / 2016 which included new technologies as advanced oxidation.

The reconstruction of the plant also gave the possibility to prepare the plumbing for “plug and play” testing of external systems by taking a part current of the process water anywhere in the treatment system and afterwards returning it for retreatment in the main system. Region Zealand expects phenoxy acids to be a high cost remediation area in the near future and there by the need for new remediation technologies is obvious. Furthermore, the site gives the possibility for private companies, university’s etc. to test and validate new products and technologies.

PRACTICAL

Access to the site

Transport of containers and equipment can be done with a crane truck.

Minimum crane outreach is 10 meters (front mounted).

Crane trucks greatest width at < 10 meters outlays must not exceed 2.5 meters.

Appropriate support plates must be used.

Equipment to be set up in the barn can be moved with pallet trucks. Use appropriate protective plates at work so that the epoxy floor is not damaged.

Facilities

The site has the following facilities:

The site is equipped with the following facilities:

Small kitchen

Meeting room for 36 people

Toilet

AV-equipment

Wi-Fi

Video surveillance

Test infrastructure

Transport of containers and equipment can be done with a crane truck.

Minimum crane outreach is 10 meters (front mounted).

Crane trucks greatest width at < 10 meters outlays must not exceed 2.5 meters.

Appropriate support plates must be used.

Equipment to be set up in the barn can be moved with pallet trucks. Use appropriate protective plates at work so that the epoxy floor is not damaged.

Requirements for project owners

Project owners

In order to ensure, among other things, optimal conditions for each individual project, Region Zealand must approve all projects. Please submit a project application with, in all confidentiality, full transparency in relation to technical and chemical details. Template is available here: dansk, English.

The project owner holds the sole responsibility of obtaining necessary permission(s) of the local municipality. Documentation must be shared with Region Zealand.

Before access to the site, we also ask you to sign an agreement, which commits the project owner to take responsibility for any damages under Danish law and for not increasing the cost of future efforts to remediate the contaminated site.

All visitors

Please treat the facilities with respect and tidy up after yourselves.

Technical documents

- Ansøgningsskema Brug af testgrund ved Stengården dansk version 30.06.2023

- Application form Use of test site Stengården English version 30.06.2023

- DGU205.253

- DGU205.341

- DGU205.62

- DGU206.1202

- DGU206.1237

- DGU206.1238

- DGU206.1259

- DGU206.1315

- DGU206.1316

- DGU206.1372

- DGU206.1373

- DGU206.1548

- DGU206.1549

- DGU206.1550

- DGU206.1551

- DGU206.1817

- DGU206.1818

- DGU206.1819

- DGU206.1837

- DGU206.1838

- DGU206.1839

- DGU206.1840

- DGU206.1841

- DGU206.1843

- DGU206.193

- DGU206.194

- DGU206.195

- DGU206.2072

- DGU206.2163

- DGU206.2164

- DGU206.276

- DGU206.306

- DGU206.465

- DGU206.482

- DGU206.72

- DGU206.725

- DGU206.843

- Etablering af 3 nye boringer og modellering af stoftranportscenarier med bilag

- Historisk redegørelse

- Stengårdens Losseplads - Bilag

- Stengårdens Losseplads - Rapport

- Undersøgelse af forureningsfanen 2008

Ongoing projects

BioBassin

The purpose of the BioBassin project is to develop an innovative method for degradation of Phenoxy acids by using bacterial cultures that are commonly found in nature and/or wastewater. The project is carried out in cooperation with Aarhus University. The final goal is to build a plant on large scale based upon the experiences gained in the project.

The period of the project is estimated to be 3 years. The method takes several parameters into consideration, such as regulation of residence time, surface area and oxygen requirements. This is a way to optimize the degradation compared to traditional sand filtration.

A pilot-scale system has been developed, consisting of three tanks with different types of filling material: 1) sand 2) sand + peat 3) custommade rockwool.

Projektdokumenter

BioRem

Projektdokumenter

Membrane filtration and advanced oxidation

Pilot scale test of membrane filtration combined with advanced oxidation processes as an alternative to traditional treatment on activated carbon.

Phase 1 is a literature study to determine promising combinations of membranes and contaminants. Phase 2 is a pilot scale test of the ability of the membranes to retain dissolved contaminants. Phase 3 is a pliot scale test of the ability of different advanced oxidation processes to treat the concentrated retentate.

2018-2019 Phase 2 was in operation at the Innovation Garage with unpromising results concerning chlorinated solvents.

In 2020 Phase 2 will be carried out in Region Zealand targeting different pesticides.

Projektdokumenter

UPWATER

The goal is to develop and validate the performance of bio-based engineered natural treatment systems designed as mitigation solutions to protect groundwater pollution. The performance of these measures will be evaluated and their scaling-up will be simulated to assess the potential environmental benefits for a broad adoption. In addition, the project aims at developing water quality models to simulate the effect of mitigation efforts.

EU Horizon project involving 11 partners from European countries and two australian organizations.

Read more here: https://www.upwater.eu/